Each year, more than 94,000 forklift accidents are reported in the United States. Suffice to say, operator training isn’t enough to reduce the number of incidents, however, it is the most important component. Naturally the best approach to preventing forklift accidents is one that combines the efforts of every person, business and organization involved.

As for forklift manufacturers, Toyota decided to take the lead role. The result was creating the world’s first System of Active Stability™ (SAS).

Derived from automotive technology, SAS is able to electronically monitor and control forklift operations, helping to reduce the risk of accidents. In short, when the SAS system detects instability, its advanced sensors simultaneously signal and engage the appropriate controller. The Active Control Rear Stabilizer or the Active Mast Function Controller adds stability and helps avoid accidents or injuries.

Toyota’s System of Active Stability & Forklift Safety

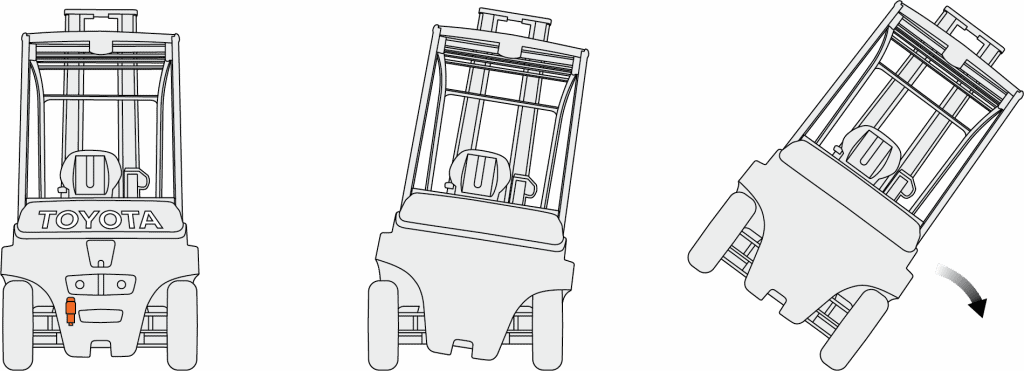

Toyota’s SAS uses patented technology to sense various factors that lead to potential lateral instability. When those conditions are detected, the SAS instantly locks a hydraulic cylinder on the rear steer axle, changing the forklift’s stability footprint from triangular in shape to rectangular. The resulting increase in stability reduces the likelihood of a lateral overturn.

When it senses instability, SAS instantly engages the Swing Lock Cylinder to stabilize the rear axle, creating the lateral stability needed to help reduce the risk of lateral tip-overs.

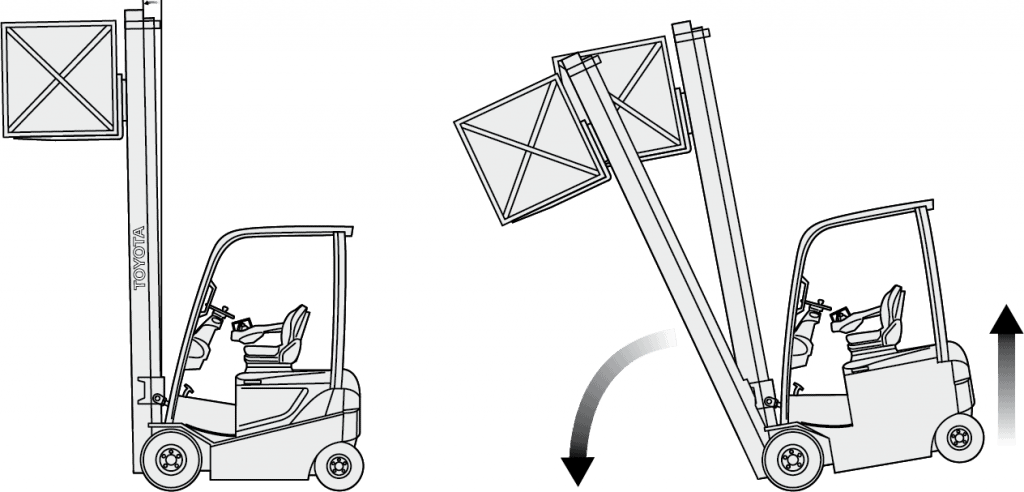

Similar in operation to the active rear stabilizer control, the Active Mast Function Controller system uses the same patented technology to sense various factors that lead to potential longitudinal instability. When the SAS controller senses potential longitudinal instability, two systems are activated to help reduce the chances of forward or rearward tip-overs: forward tilt angle control and rear tilt speed control.

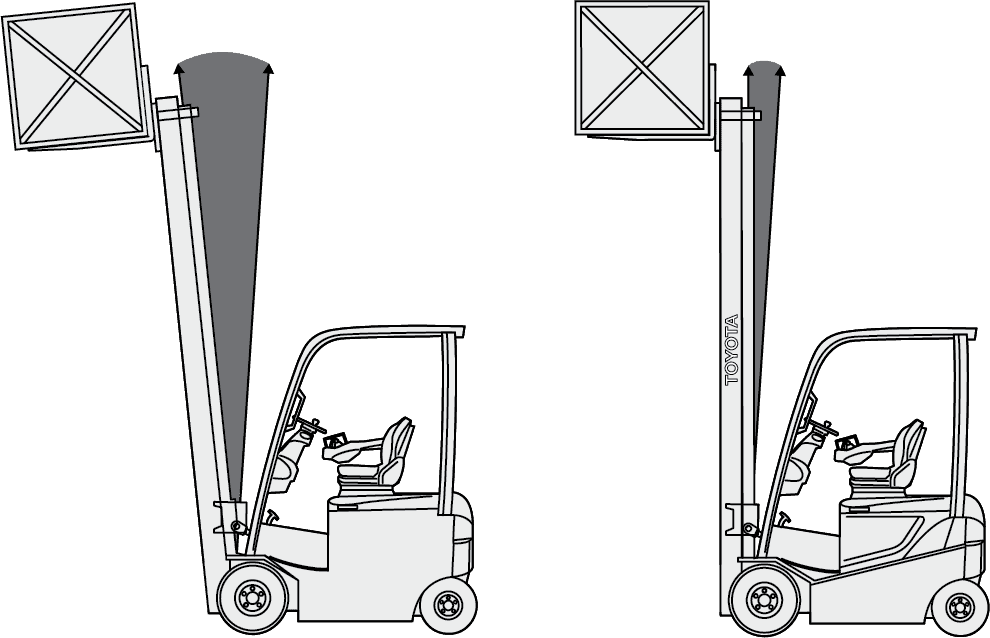

Automatic Fork Leveling Control adjusts the mast so that the forks are level with the ground for ease in retreiving pallets at high levels.

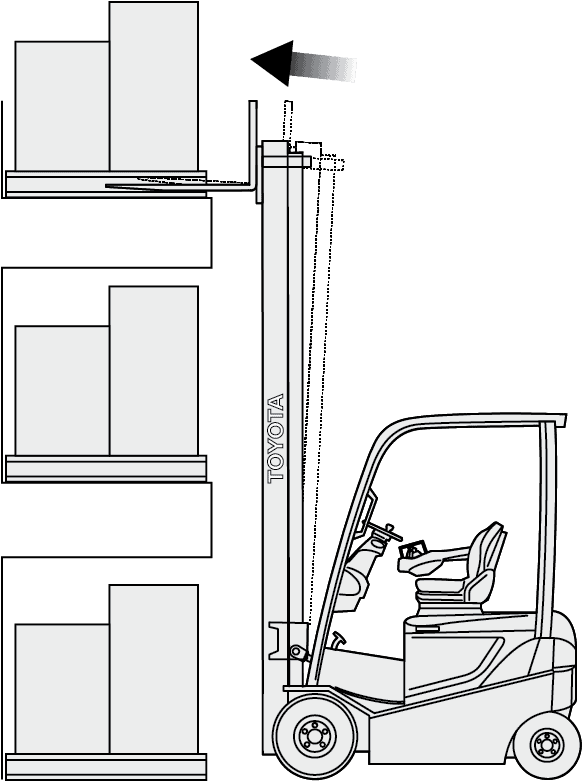

Forward Tilt Angle Control will sense load weight and mast height, then automatically override the operator’s manual control and limit forward tilt to decrease the chance of spilling a load or tipping the forklift forward.

Rear Tilt Speed Control utilizes the same load and mast height sensors to govern the mast’s reverse tilt speed to half, thereby decreasing the chances of spilling unsecured loads or tipping the forklift backward.

Toyota Forklifts are on the cutting edge of forklift safety. Summit ToyotaLift would enjoy the chance to show you why Toyota sells the most forklifts worldwide. Set up a demo at your facility throughout the Northeast. Contact us today for more information.