Forklifts are vital machines used in various industries, such as warehousing, manufacturing, and logistics, to lift, move, and transport heavy loads. These powerful machines have specific operating capacities, which determine their ability to handle different loads safely. However, there are instances when a forklift may undergo a derate, a process that reduces its lifting capacity. In this article, we will explore what forklift derate entails, why it is important, and its implications for workplace safety and efficiency.

Understanding Forklift Derate

Forklift derating refers to the reduction of a forklift’s rated lifting capacity due to specific factors or conditions. These factors may include changes in the operating environment, alterations in the forklift’s components, or modifications in the load configuration. When a forklift undergoes derating, its maximum lifting capacity is adjusted to ensure safe and efficient operations.

Reasons for Forklift Derate

- Environmental Factors: Environmental conditions such as temperature, altitude, and surface conditions can affect a forklift’s performance. Extreme temperatures, high altitudes, or rough surfaces can influence the forklift’s ability to lift loads safely. In such cases, the forklift may need to be derated to account for these challenging conditions.

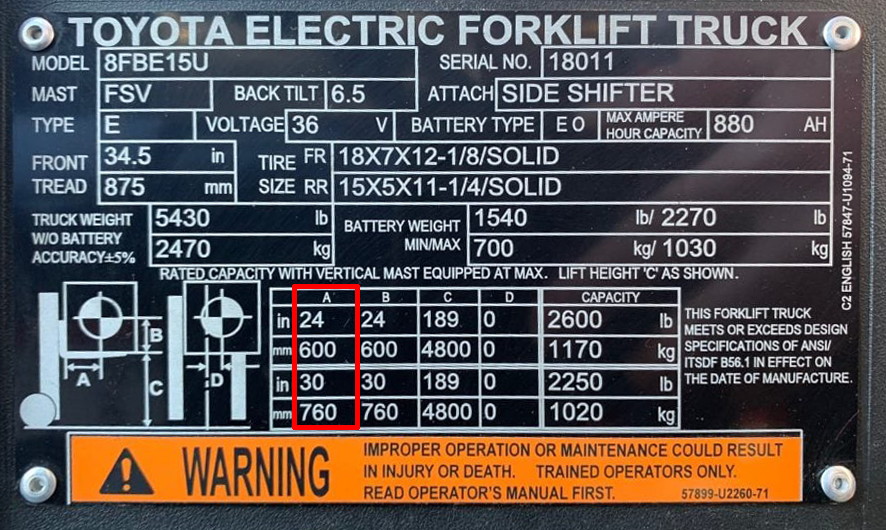

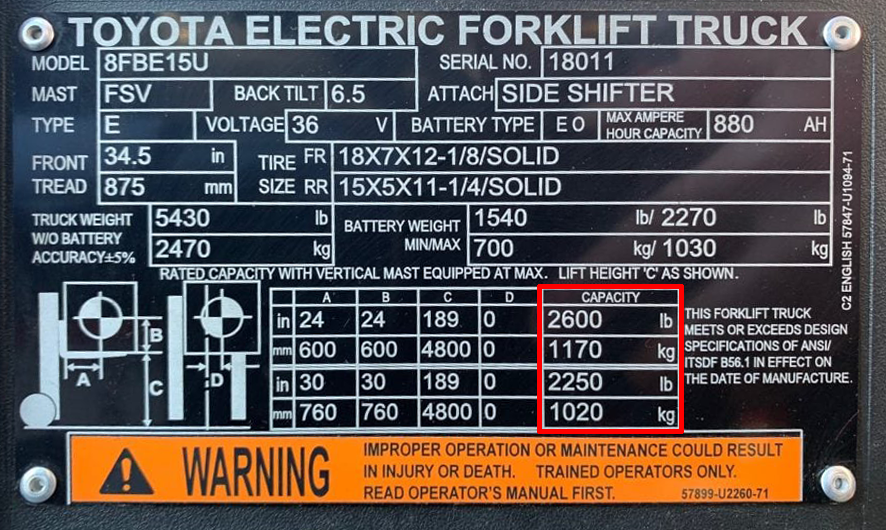

- Component Changes: Any modifications or replacements of essential components in a forklift, such as the mast, attachments, or tires, can affect its lifting capacity. When upgrading or changing these components, it is crucial to ensure that the forklift’s rating is adjusted accordingly to maintain safe operations.

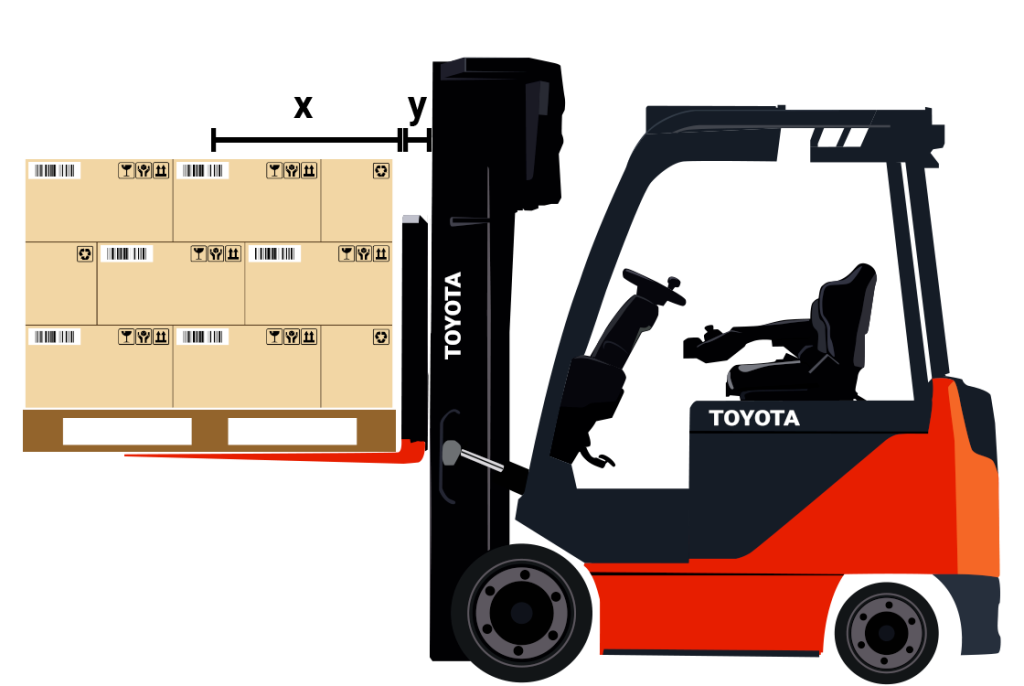

- Load Configuration: The way a load is positioned and distributed on a forklift’s forks significantly impacts its stability and lifting capacity. If a load is unevenly distributed or extends beyond the forklift’s recommended limits, it can lead to instability or tipping. In such cases, the forklift may need to be derated to prevent accidents and ensure safe load handling.

Implications of Forklift Derate

- Safety Enhancement: Forklift derating plays a vital role in maintaining workplace safety. By reducing the lifting capacity to account for environmental factors or load configurations, the risk of accidents, tip-overs, and equipment damage is minimized. Derating helps ensure that forklift operators work within safe limits, preventing incidents that could harm personnel, infrastructure, or inventory.

- Compliance with Regulations: Forklift derate procedures often align with safety regulations and standards set by governing bodies such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute). By adhering to these guidelines, businesses can demonstrate their commitment to workplace safety, mitigate legal risks, and avoid penalties associated with non-compliance.

- Operational Efficiency: Derating a forklift, when necessary, helps optimize its performance and longevity. By considering factors like environmental conditions and load configurations, operators can use the forklifts within their safe operating limits, ensuring consistent and efficient productivity. Derating also helps prevent excessive wear and tear on the forklift, reducing maintenance costs and downtime.

How to Quickly Derate a Forklift with OSHA’s Field Calculation

Derating is a timely process that you might not be able to do especially if you only need to lift 1 odd shape load infrequently. Therefore, if you just need a quick calculation to make sure you are not overloading your forklift you can use the quick field calculation given by OSHA. Please note that this formula assumes you are not lifting a product past the height of 2 pallets.

OSHA Field Derate Formula:

Original Horizontal Load Center / New Horizontal Load Center x Rated Capacity

Rated Horizontal Load Center

Rated Capacity

For example, if you have a forklift rated at 3000 lbs. at 24 in load center and then an attachment that lowers your lifting capacity by 150 lbs. and adds an effective thickness of 4 inches then you’d be looking at (24/(24+4))*(3000-150) = 2571 lbs. max lift capacity.

You can also use Summit’s Forklift De-Rate Calculators to quickly find your de-rated capacity.

Note: Only use the field calculations to estimate the reduced lifting capacity if the manufacturer’s instructions are not available. This calculation method will not produce exact load reduction figures and you should always assume a 50 lbs. margin of error. Only use the field calculation as a guideline. If you are adding an attachment to the forklift you will need a new data plate made to account for this. Contact Summit ToyotaLift to get a new official derate data plate for your forklift.

Forklift derate is an essential aspect of maintaining workplace safety and optimizing forklift operations. By adjusting the lifting capacity to account for environmental conditions, component changes, and load configurations, businesses can prevent accidents, comply with safety regulations, and improve operational efficiency. It is crucial for forklift operators and maintenance personnel to understand the significance of derating and follow proper procedures to ensure the safe and effective use of these powerful machines in industrial settings. Please contact Summit if you have any questions on derating a forklift.